Prismatic Cells Vs. Cylindrical

When looking to make the switch to Lithium there are many benefits, however not all Lithium Batteries are made the same.

There’s Prismatic and there is Cylindrical…

Prismatic Lithium Cells

Prismatic Cells are the superior type of Lithium cell for uses in any battery that is in a non-stationary environment.

However, there’s more to the construction of a Lithium Battery, including cell type, assembly, and materials used.

Cylindrical vs Prismatic

Cylindrical cells are typically made quicker and cheaper in comparison to Prismatic Lithium Cells, but at what cost?

Cylindrical 28650 arrays require dozens of spot weld connections. Spot welds are by nature a brittle fixing and the fact you are relying on so many connections make the likelihood of failure greater. Specialised equipment is also required to make the spot welds and they are difficult to fix if there are any issues with an individual weld.

When comparing Prismatic cells there are also multiple tiers of quality in the construction and the connection options.

Cost vs Quality

Some prismatic cells are constructed with plastic outer cases. The type of plastic varies, and the cheaper cells use lightweight plastics of the cheapest composition available. The casing is an important point if there are problems with the Lithium cell. The melting point of cheaper plastics can be as low as 150C. Even hard case prismatic cases using better ABS plastic have a melting point of 200C.

Why is the melting point of plastic cases important?

If a Lithium cell is damaged or has a manufacturing fault, then it can go into error. Cheaper cells manufactured under less strict conditions may get something as simple as a single grain of dirt encapsulated in the cell which becomes a high resistant point and will heat up and can cause a cell to fail. Therefore, it is very important that the cells are constructed, and systems audited under strict international ISO standards to ensure these manufacturing issues don’t occur.

The cell fails by creating a short between the anode and cathode layer. In the unlikely event, the temperature can rise quickly. When the melting point of the case is low then very soon the case will melt around that hot point. With an ingress of oxygen, the reaction is fuelled and becomes very difficult to stop. There are three elements to combustion. Heat, fuel, and oxygen. Cheaper prismatic cells can heat with manufacturing intolerances being the cause, the plastic itself becomes the fuel and when it melts it allows the third ingredient, oxygen.

The safest alternative is utilising hard case metal cell enclosures. Aluminium has a melting point of 660C. A substantially higher temperature than the 200C of the plastic cell cases and the battery outer cases. Aluminium enclosures are harder to penetrate and do not provide fuel like plastic does. The outer battery case acts as the second layer of protection and when made of hard metal like Aluminium, it will be less likely to fail and allow the rush of oxygen in.

Battery Construction

Within the hard case metal, there are also different fixing options. The cheapest option is a metal tab that presents the positive and negative link. These tabs also require a spot weld to make a connection. The best option is a threaded bolt connection. This enables the most robust link and is easily serviced if required.

How the cells are linked together into a battery array is also a critical point. To make a 12V battery you need either 4 or 8 cells put into a serial array. The cheapest way is with individual links. The more robust connection is a customised Printed Circuit Board (PCB) which has embedded copper connections and turns the whole array into a mechanically rigid block.

What to look out for?

In summary, there are many considerations when manufacturing a battery and simple claims of having prismatic cells is a small part of the battery.

When looking at purchasing your next Lithium Battery, the below checklist is something you should take into consideration:

- Does the battery use prismatic cells

- Is the prismatic cell enclosed in an Aluminium outer case

- Are the connections made using bolts and not welded tabs

- Is the array held into a block with a rigid PCB cell link board

- Are the cells made by a company with international ISO accreditation

- Are the cells compliant with 62619 international standards

- Is the final assembly gone through charge and discharge tests during an auditable QA system with a QMS system in place

- Triple Guard Protection (Hard case metal cell protection, Electrical BMS protection, and hard case metal outer battery enclosure)

Prismatic LiFePO4 battery cells

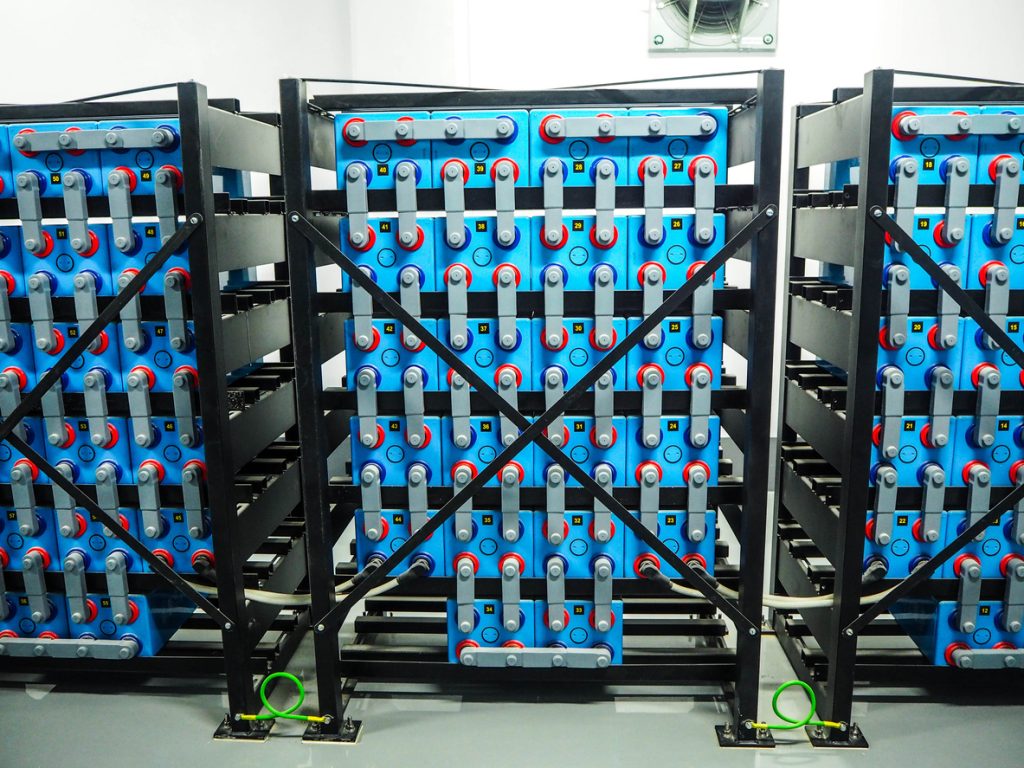

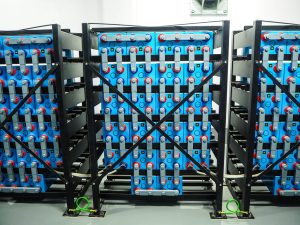

These LFP (LiFePO4) battery cells are durable, reliable, safe and powerful. They are perfect to use in battery packs for renewable energy storage systems.

These prismatic battery cells have screw terminals, making them super easy to assemble together, they are like LEGO. They are also very easy to replace in future upgrades. No soldering required.

3.2v105 Ah

- Capacity: 105 Ah

- Nominal voltage: 3,2 V

- Max voltage: 3,65 V

- Min voltage: 2,5 V

- Energy: 336 Wh

- Weight: 1,98 kg

- Dimension: 130 x 36 x 200 mm

- Volume: 0,936 L

- Gravimetric energy density: 170 Wh/kg

- Volumetric energy density: 359 Wh/L

- Cycle life: 4.000 cycles at 80 % DOD (Depth of Discharge)

What Are Prismatic Cells

A prismatic cell is a cell whose chemistry is enclosed in a rigid casing. Its rectangular shape allows efficiently stacking multiple units in a battery module. There are two types of prismatic cells: the electrode sheets inside the casing (anode, separator, cathode) are either stacked or rolled and flattened.

For the same volume, stacked prismatic cells can release more energy at once, offering better performance, whereas flattened prismatic cells contain more energy, offering more durability.

Prismatic cells are mainly used in energy storage systems and electric vehicles. Their larger size makes them bad candidates for smaller devices like e-bikes and cellphones. Therefore, they are better suited for energy-intensive applications.

The Main Differences Between Prismatic and Cylindrical Cells

Shape is not the only thing that differentiates prismatic and cylindrical cells. Other important differences include their size, the number of electrical connections, and their power output.

Size

Prismatic cells are much larger than cylindrical cells and hence contain more energy per cell. To give a rough idea of the difference, a single prismatic cell can contain the same amount of energy as 20 to 100 cylindrical cells. The smaller size of cylindrical cells means they can be used for applications that require less power. As a result, they are used for a wider range of applications.

Connections

Because prismatic cells are larger than cylindrical cells, fewer cells are needed to achieve the same amount of energy. This means that for the same volume, batteries that use prismatic cells have fewer electrical connections that need to be welded. This is a major advantage for prismatic cells because there are fewer opportunities for manufacturing defects.

Power

Cylindrical cells may store less energy than prismatic cells, but they have more power. This means that cylindrical cells can discharge their energy faster than prismatic cells. The reason is that they have more connections per amp-hour (Ah). As a result, cylindrical cells are ideal for high-performance applications whereas prismatic cells are ideal to optimize energy efficiency.

Example of high-performance battery applications include Formula E race cars and the Ingenuity helicopter on Mars. Both require extreme performances in extreme environments.

Why Prismatic Cells Might Be Taking Over

The EV industry evolves quickly, and it’s uncertain whether prismatic cells or cylindrical cells will prevail. At the moment, cylindrical cells are more widespread in the EV industry, but there are reasons to think prismatic cells will gain in popularity.

First, prismatic cells offer an opportunity to drive down costs by diminishing the number of manufacturing steps. Their format makes it possible to manufacture larger cells, which reduces the number of electrical connections that need to be cleaned and welded.

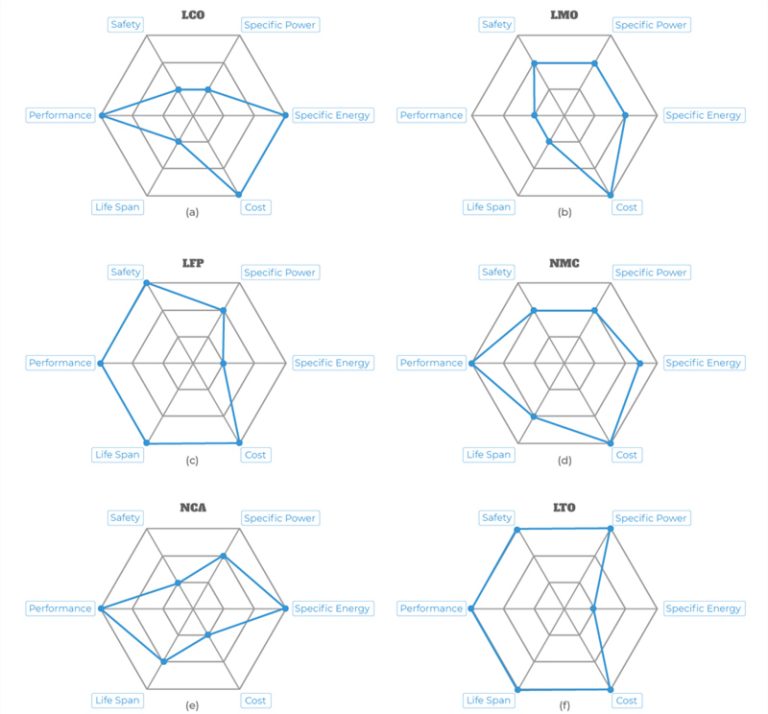

Prismatic batteries are also the ideal format for the lithium-iron phosphate (LFP) chemistry, a mix of materials that are cheaper and more accessible. Unlike other chemistries, LFP batteries use resources that are everywhere on the planet. They do not require rare and expensive materials like nickel and cobalt that drive the cost of other cell types upward.

There are strong signals that LFP prismatic cells are emerging. In Asia, EV manufacturers already use LiFePO4 batteries, a type of LFP battery in the prismatic format. Tesla also stated that it has begun using prismatic batteries manufactured in China for the standard range versions of its cars.

The LFP chemistry has important downsides, however. For one, it contains less energy than other chemistries currently in use and, as such, can’t be used for high-performance vehicles like Formula 1 electric cars. In addition, battery management systems (BMS) have a hard time predicting the battery’s charge level.

Prismatic Cells in Energy Storage Systems

When it comes to battery pack production demand, energy storage systems (ESS) are just as important as electric vehicles. ESSs are already using prismatic cells and it is very likely that they will keep using them. Prismatic cells have a longer cycle life, are less dangerous, and come at a low cost compared to cylindrical cells.

Primastic cell

The Switch to Prismatic Batteries

With its tabless cell design, high energy density, and low manufacturing cost, Tesla’s 4680 cylindrical cell is probably the most noteworthy battery cell at the moment. But recently, Elon Musk has talked about the advantages of prismatic cells, and Tesla has begun using them in certain car models.

The 4680 cylindrical cells haven’t been replaced by prismatic cells yet, but Tesla’s next move will be telling of what the future holds. Will they replace the 4680’s Nickel-Cobalt-Aluminum oxide (NCA) chemistry with the LFP chemistry? If so, will they switch to prismatic cells, the preferred format for this chemistry? With the increased cost of raw materials around the world, it is a strong possibility.

LifePO4 Batteries Related Products:

Related Products Application:

LifePO4 Batteries Related Posts:

Tag in this article: #LiFePO4 Battery

Tips: more detail information, for deep cycle LiFePO4 battery。